Introduction

In the dynamic world of industrial tools and equipment, spring balancers stand out for their innovative approach to enhancing productivity and reducing operator fatigue. At Asian Air Tools, we specialize in crafting premium quality spring balancers that are engineered to meet the diverse needs of various industries. Our products exemplify cutting-edge technology, making tools and equipment feel virtually "weightless" through precise wire rope tension equalization.

Manufacturing

Our manufacturing process is rooted in precision and excellence, employing advanced techniques to produce spring balancers that offer unrivalled durability and performance. From the high-tensile lightweight Aluminium Alloy to the forged steel hooks, every component is chosen for its strength and longevity, ensuring minimal downtime and maintenance-free operation.

Why Asian Air Tools is Best

Asian Air Tools stands unparalleled in the spring balancer market for several reasons. Our balancers are designed to provide constant tension with a spring and a tapered drum, ensuring smooth operation. With our broad range of products, including Braking Balancers, "ECO" Spring Balancers, Clean Room Balancers, and ASB Series Tool Balancers, we cater to a wide spectrum of industrial applications.

Types of Spring Balancers

1. Braking Balancer

The Asian Air Tools Braking Balancer revolutionizes tool handling with its innovative one-way clutch lining braking system. Engineered for precision and safety, it allows tools to descend slowly, mitigating snapback risks and enhancing workplace safety. Its versatility is unmatched, serving both as a traditional balancer and, with the brake disengaged, as a dynamic tool positioning system. Ideal for high-paced environments, it promises efficiency, safety, and a maintenance-free operation, making it a pivotal addition to any industrial setting.

2. "ECO" Spring Balancer

The "ECO" Spring Balancer from Asian Air Tools sets the benchmark for eco-friendly tool suspension. With a focus on sustainable operation, it features a polished casing, food-grade grease, and stainless-steel components, ensuring no contamination in sensitive environments like food processing or pharmaceuticals. This balancer combines environmental responsibility with uncompromised performance, offering a clean, safe, and efficient tool-handling solution that aligns with modern green manufacturing practices.

3. Clean Room Balancer

Designed for environments where cleanliness and contamination control are paramount, the Asian Air Tools Clean Room Balancer excels in performance and hygiene. Its enclosed casing prevents dust dispersion, making it perfect for clean rooms. With conductive casing for easy grounding and a flexible installation bracket, it meets stringent clean room standards. Whether in semiconductor manufacturing or biotech, this balancer ensures precise tool positioning while upholding clean room integrity.

4. ASB Series Tool Balancers

The ASB Series Tool Balancers by Asian Air Tools redefine "zero gravity" tool holding, delivering unparalleled ease and precision in tool positioning. With a range of capacities to suit various industrial needs, these balancers are designed for effortless tension adjustment and robust construction, ensuring long-term reliability. Ideal for suspending a wide array of tools, the ASB Series promotes optimal workplace efficiency and operator comfort, solidifying its status as a must-have for any assembly line or engineering workshop.

Quality

Quality is at the core of our operations. Each spring balancer is a testament to our commitment to durability, incorporating a highly durable spring design and rugged construction for maximum operation life. Our commitment to quality and innovation ensures that our products deliver an excellent working force, contributing significantly to minimizing operator fatigue.

Performance

Performance is where our spring balancers truly shine. Designed for maintenance-free operation with minimum downtime, they are equipped with features like external tension adjustment, automatic drum lock, and a swivel on top hook for optimal efficiency and safety.

Innovative and Creative

Our spring balancers are a product of innovation, incorporating features such as a tapered cable drum and manual drum lock for easy and quick maintenance. The ECO Spring Balancer showcases our commitment to eco-friendly solutions with its buffed and barrel-polished casing and synthetic food-grade grease.

Applications

Asian Air Tools' spring balancers are versatile and ideal for suspending electric or pneumatic power tools, jigs, fixtures, or welding equipment. They are perfect for assembly lines/weld lines in automotive, engineering, white goods industries, and even in food-grade environments, thanks to our food-grade balancers.

Asian Air Tools redefines the standards of industrial efficiency with our superior range of spring balancers. Engineered for durability, performance, and innovation, our products are designed to offer great profits to customers by enhancing productivity and ensuring the safety of production lines. With Asian Air Tools, elevate your operational efficiency to new heights, making tools and equipment operation effortless and more productive.

Asian Spring Balancer

| SR.NO. | BALANCING CAPACITY | MODEL NO | BODY TYPE | ROPE LENGTH | |

|---|---|---|---|---|---|

| MIN (KG) | MAX (KG) | ||||

| 1 | 0.5 | 2 | AAT-SB-2.0 SHEET METAL | SLEEK BODY | 1.5 MTR |

| 2 | 1 | 3 | AAT-SB-3.0 SHEET METAL | ROUND BODY | 1.5 MTR |

| 3 | 2.5 | 5 | AAT-SB-5.0 SHEET METAL | ROUND BODY | 1.5 MTR |

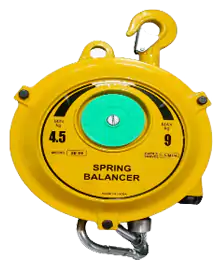

| 4 | 4.5 | 9 | AAT-SB-9.0 DAI CASTING | CLOSED BODY | 1.5 MTR |

| 5 | 9 | 15 | AAT-SB-15.0 DAI CASTING | CLOSED BODY | 1.5 MTR |

| 6 | 15 | 22 | AAT-SB-22.0 DAI CASTING | CLOSED BODY | 1.7 MTR |

| 7 | 22 | 30 | AAT-SB-30.0 DAI CASTING | CLOSED BODY | 1.7 MTR |

| 8 | 30 | 40 | AAT-SB-40.0 DAI CASTING | OPEN BODY | 1.7 MTR |

| 9 | 40 | 50 | AAT-SB-50.0 DAI CASTING | OPEN BODY | 1.7 MTR |

| 10 | 50 | 60 | AAT-SB-60.0 DAI CASTING | OPEN BODY | 1.7 MTR |

| 11 | 60 | 70 | AAT-SB-70.0 DAI CASTING | OPEN BODY | 1.7 MTR |

| 12 | 70 | 85 | AAT-SB-85.0 DAI CASTING | OPEN BODY | 1.5 MTR |

| 13 | 70 | 85 | AAT-SB-85.0 DAI CASTING | CLOSED BODY | 1.5 MTR |

| 14 | 85 | 100 | AAT-SB-100.0 DAI CASTING | CLOSED BODY | 1.5 MTR |

| 15 | 100 | 120 | AAT-SB-120.0 DAI CASTING | CLOSED BODY | 1.5 MTR |

| 16 | 120 | 140 | AAT-SB-140.0 DAI CASTING | OPEN BODY | 1.5 MTR |

| 17 | 140 | 170 | AAT-SB-170.0 DAI CASTING | OPEN BODY | 1.5 MTR |

| 18 | 170 | 200 | AAT-SB-200.0 DAI CASTING | OPEN BODY | 1.5 MTR |

| Model | capacity(kg) | Stroke(m) | Wire rope diameter(mm) |

Mass(kg) | How to adjust spring tension |

Fall-arrest device |

Drum lock device |

| ASB-00 | 0.5~1.5 | 0.5 | 2.0 | 0.2 | Ratchet | - | - |

| ASB-0 | 0.5~1.5 | 1.0 | 3.0 | 0.5 | - | - |

| Model | Capacity(kg) | Stroke(m) | Cable dia(Mm) | Mass(kg) |

| ASB-3B | 1.5-3.0 | 1.3 | 3.0 | 4.7 |

| ASB-5B | 3.0-5.0 | 1.3 | 3.0 | 8.9 |

| ASB-7B | 5.0-7.0 | 1.3 | 3.0 | 9.3 |

| Model | Maximum initial tension (Winding tension) N[kg.] |

Winding length (m) |

Additional tension (caused by pulling out the wire rope) N[kg.] |

Effective number of spring turns |

Ratchet | Wire rope diameter (Mm) |

Mass (kg) |

| AAT-3A | 18[1.8] | 3.0 | 12[1.2] | Approx.16 | • | 2.38 | 1.4 |

| AAT-3B | 18[1.8] | 3.0 | 12[1.2] | Approx.16 | - | 2.38 | 1.3 |

| AAT-5A | 25[2.5] | 3.0 | 25[2.5] | Approx.13 | • | 2.38 | 1.5 |

| AAT-5B | 25[2.5] | 3.0 | 25[2.5] | Approx.13 | - | 2.38 | 1.4 |

| AAT-10A | 49[5.0] | 4.0 | 49[5.0] | Approx.13 | • | 2.38 | 4.5 |

| AAT-10B | 49[5.0] | 4.0 | 49[5.0] | Approx.13 | - | 2.38 | 3.8 |

| Model | Capacity (kg) | Stroke (m) | Mass(kg) |

| SBC-1 | 0.5~1.5 | 1.0 | 1.2 |

After confirming the model, be sure to download and read the instruction manual before installation.

Lift up the main unit and hang it over the closed support member. An auxiliary chain or wire should be attached to the auxiliary hanger of the balancer body to prevent the balancer from falling if the upper hook or its connection parts fails. The auxiliary chain or wire should have some leeway to allow the balancer to move freely. Refer to the instruction manual of the range of necessary leeway.

When shipped, the spring tension of the balancer body is adjusted to the center of the setting load gauge. In the image, EWF-22, 15kg to 22kg Center of the load gauge=18kg

Before suspending a load, adjust the spring tension according to the weight of the load.

There are “handle type”, “ratchet type” and “worm type”.

For all ENDO balancers, turning the adjustment parts clockwise increases the spring tension, and turning counterclockwise decreases the spring tension. Adjust the spring tension so that the gauge scale for the suspended load is set to the capacity indication point.

※The lightweight model does not have a gauge, so please adjust it after suspending the load.

Lift the load and hang it in the bottom hook.

If the hook is released from your hand before the load is attached it will retract quickly potentially causing injury or damage to the balancer and or load.

The load value indicated by the gauge scale is for reference only. Make the final spring tension adjustment while checking the balancer point of the suspended work piece. The installation is now completed.

When deactivating the safety device, make sure the work load is still in place on the bottom hook to prevent the wire rope from rapidly retracting potentially causing injury and/or damaging the equipment. Make sure the work piece weight is within the tension gauge.

When deactivating the safety device, make sure the work load is still in place on the bottom hook to prevent the wire rope from rapidly retracting potentially causing injury and/or damaging the equipment. Make sure the work piece weight is within the tension gauge.